Category

Magic School Bus

Capturing the magic and delight in a child’s sketch and bringing it to reality in a manufacturable toy that can be repeated at scale.

Brief

My team was given the challenge of transforming local 4th graders drawing into a physical toy, utilizing their drawings as inspiration. Within the stack of 2 dimensional drawings we were given we dew out the most delightful features, meshing them into one final 3 dimensional toy.

My team outlined two key goals for our toy:

- How might we keep and even elevate the magic embodied in the original sketch, remaining faithful in our design.

- How might we use this experience to learn more about CNC machining and injection molding, taking these learnings and applying them to future projects.

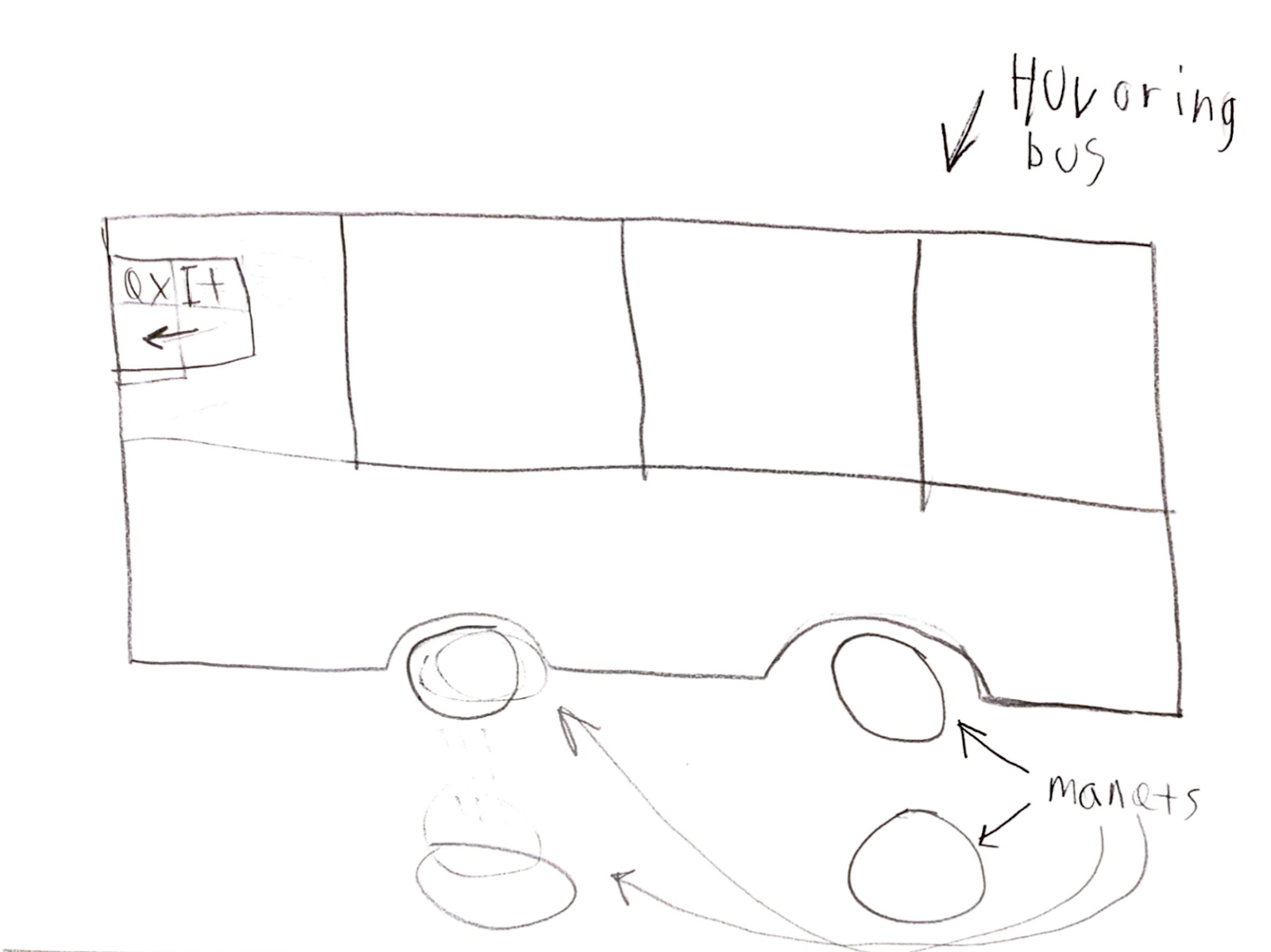

Inspiration

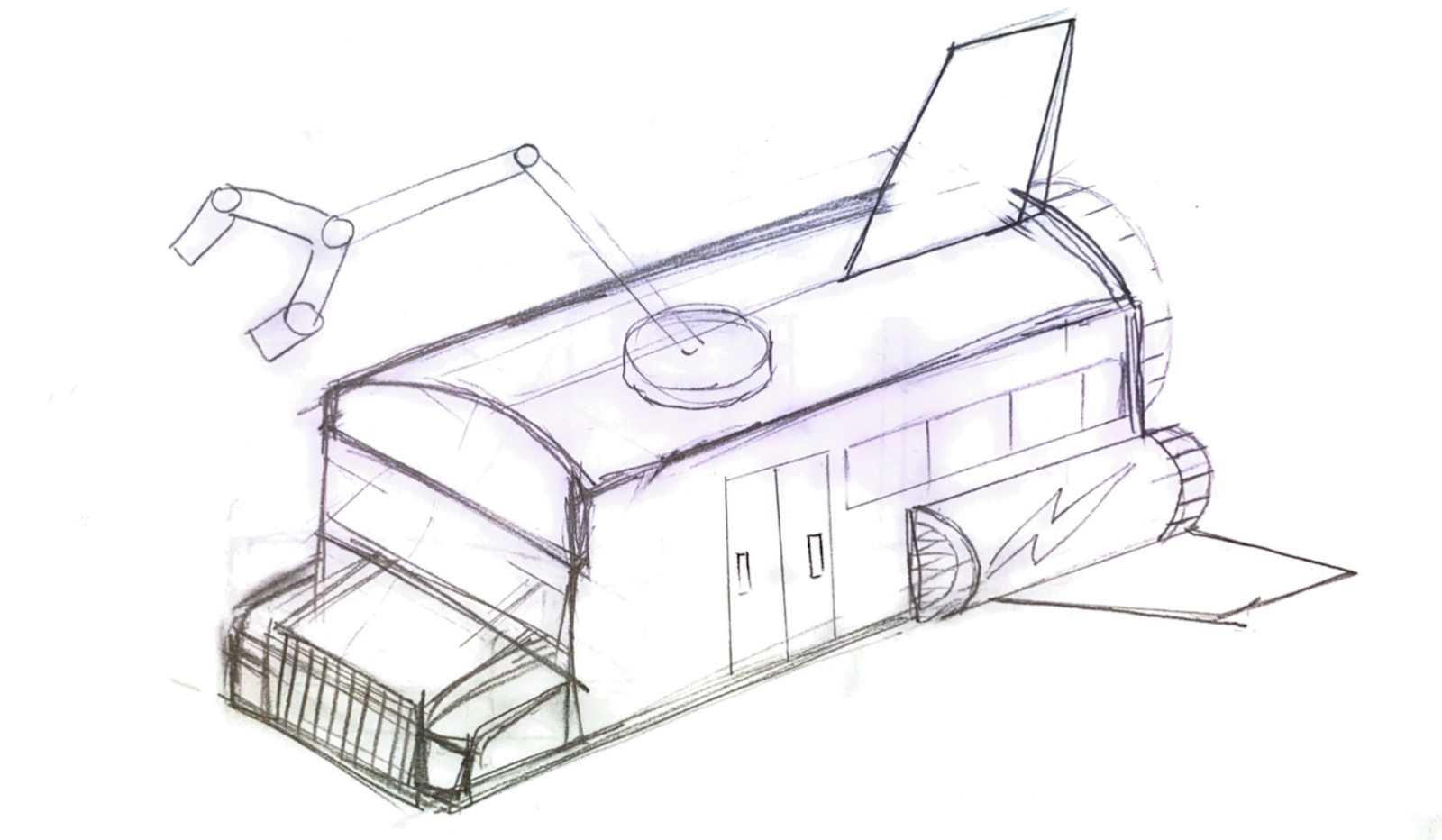

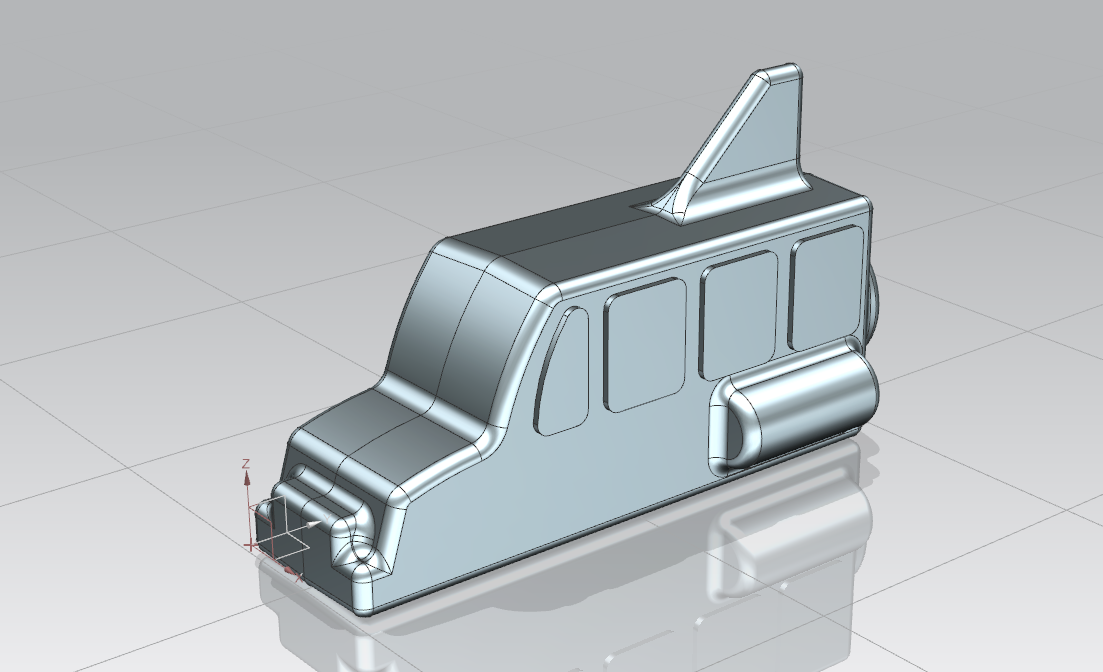

To bring their imagination to life, we first had to take their 2D sketch and reimagine it as a 3D object.

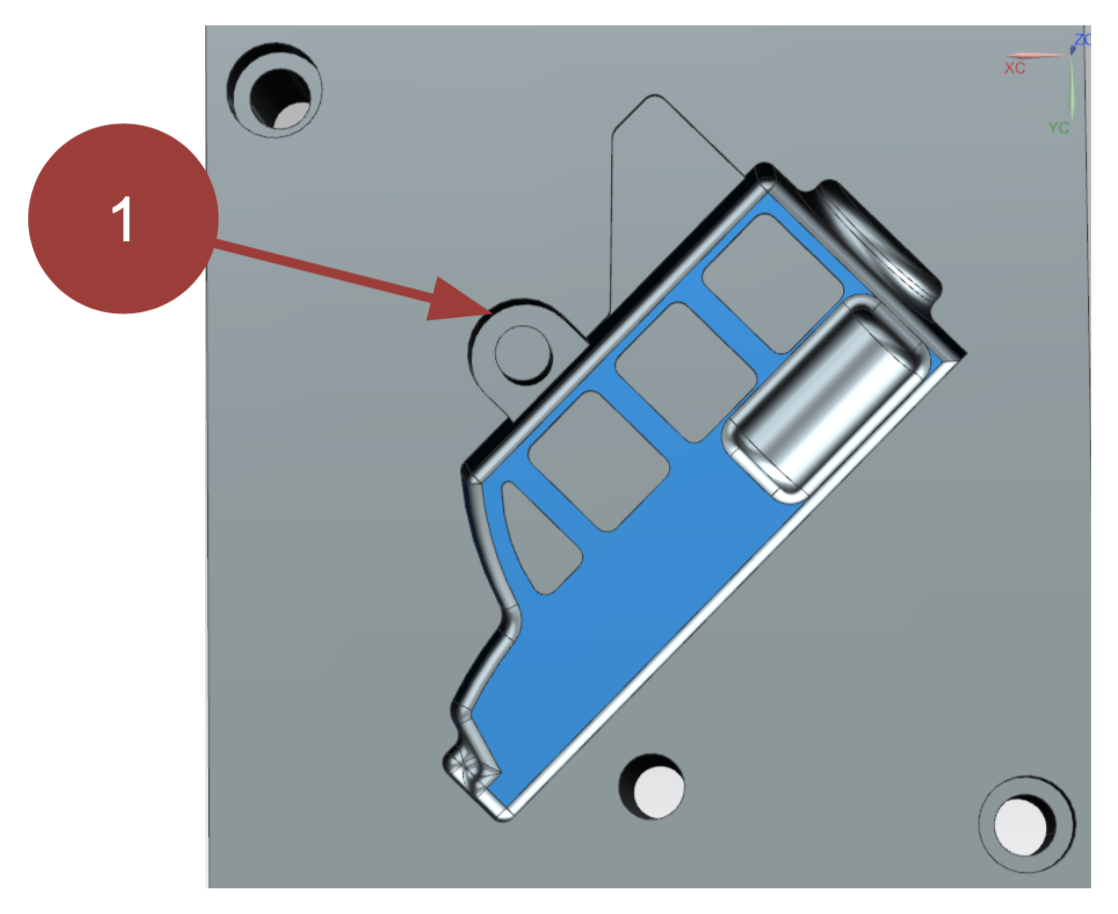

1st Round Computer Aided Design

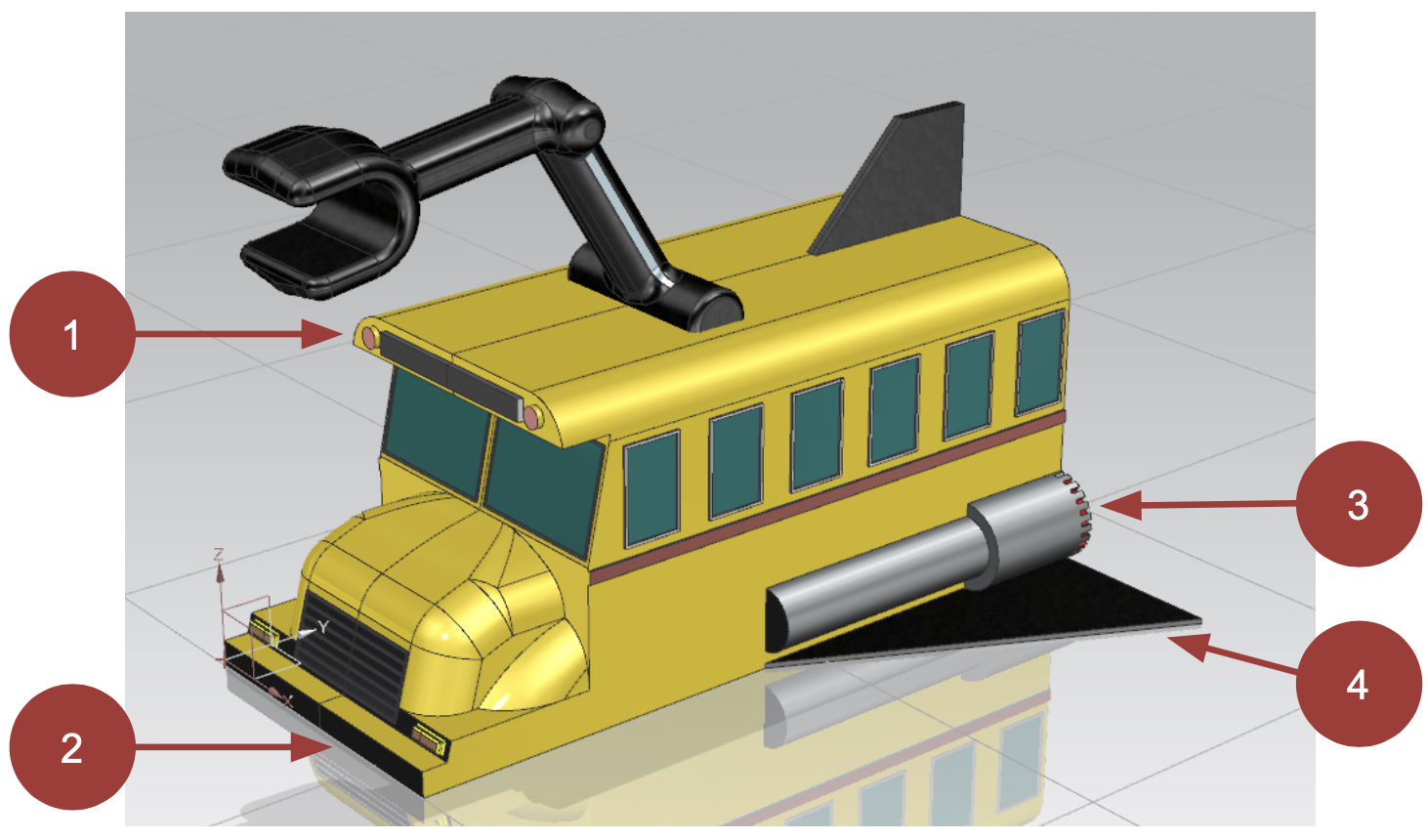

2nd Round Computer Aided Design

One Last Challenge

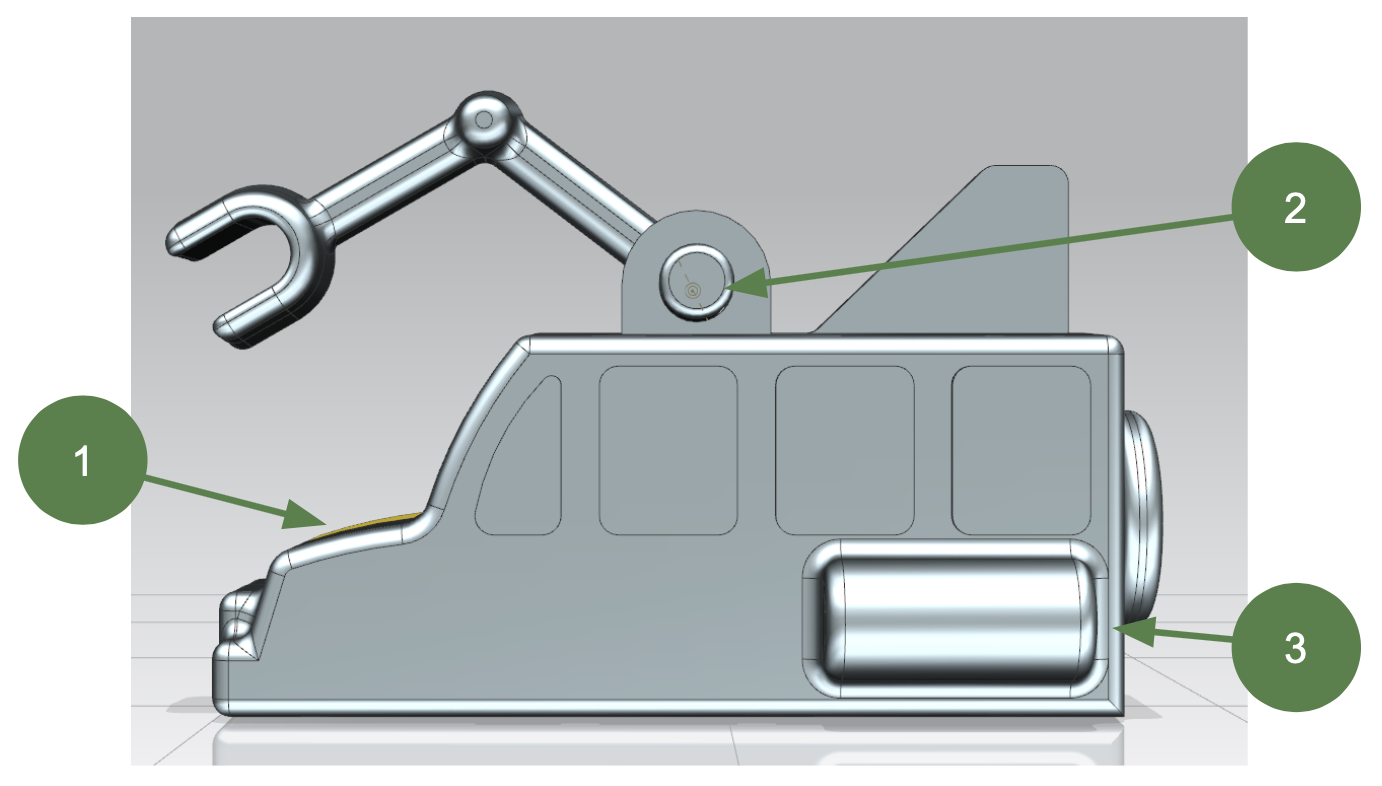

Final CAD Design

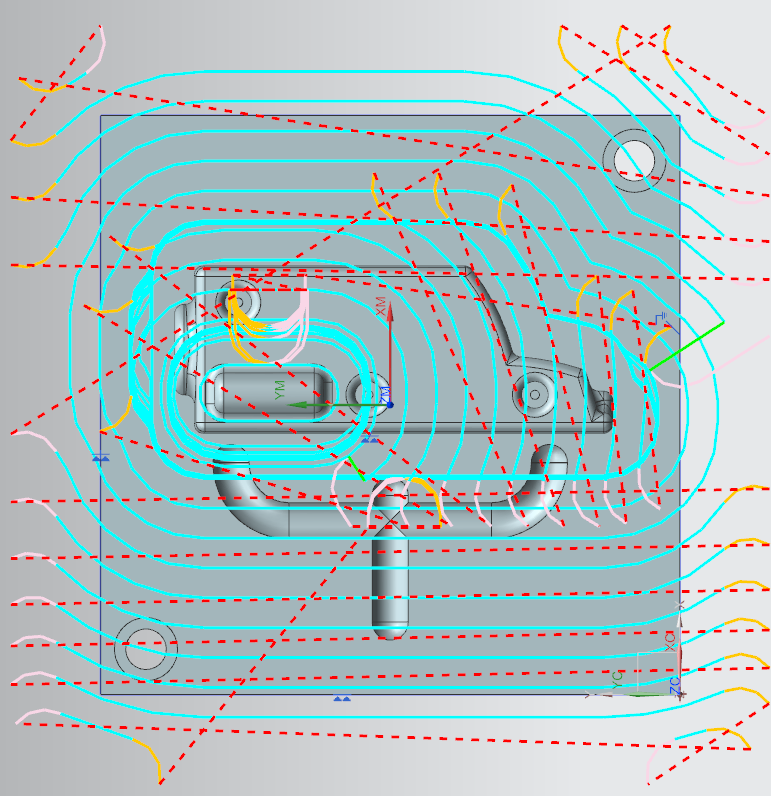

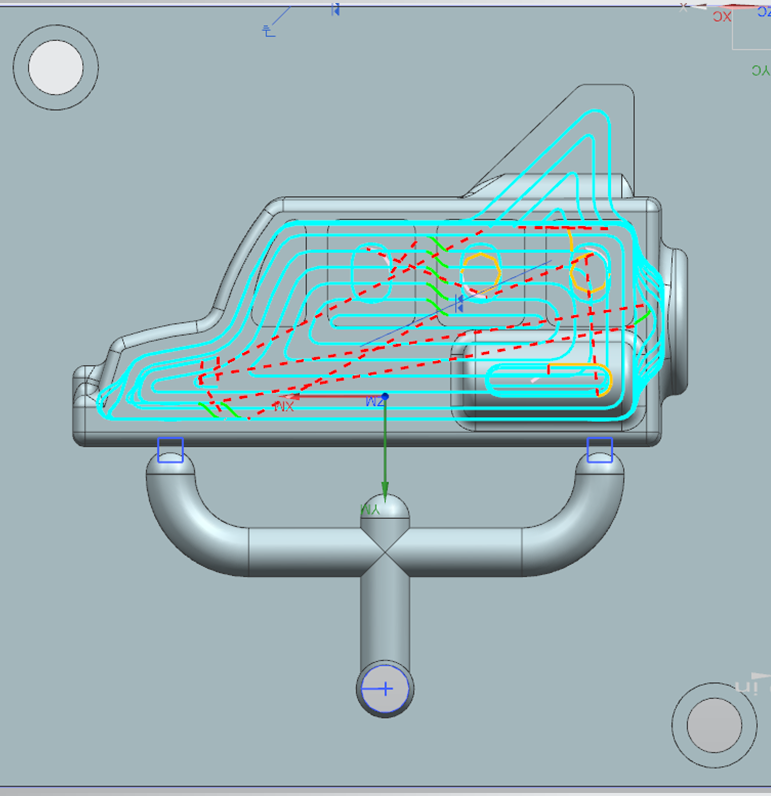

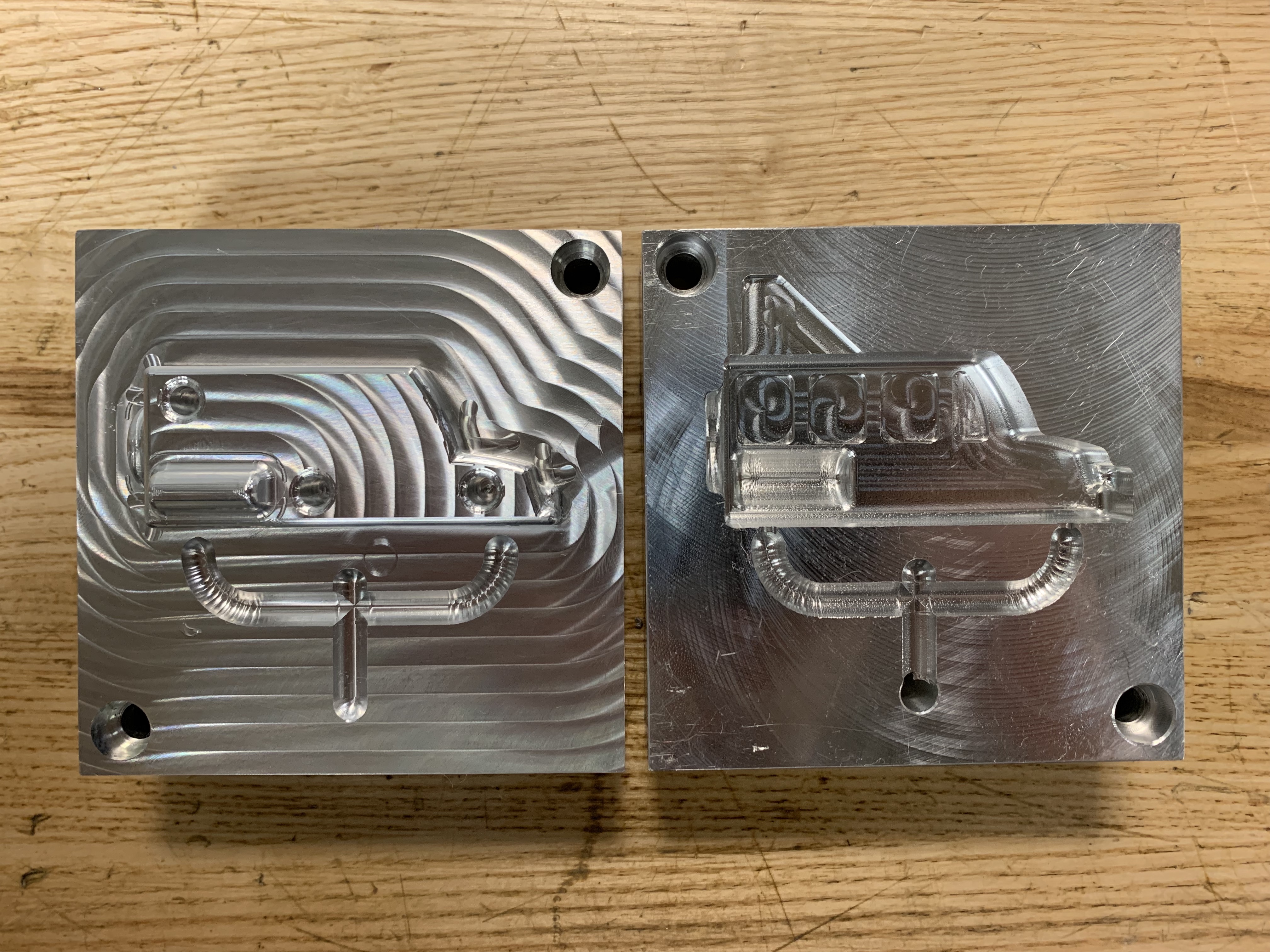

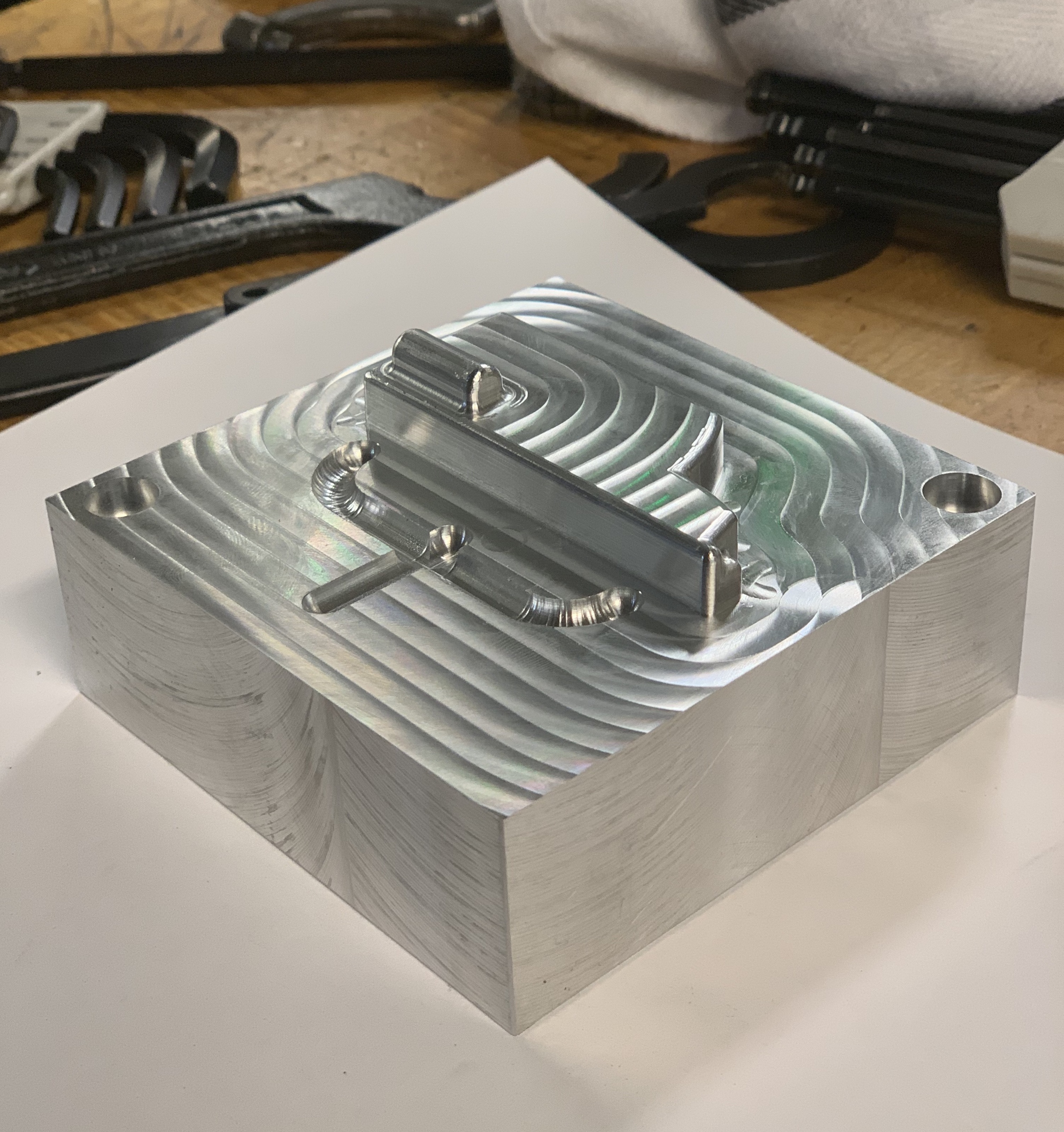

Molds &

Computer Aided Machining

Molds

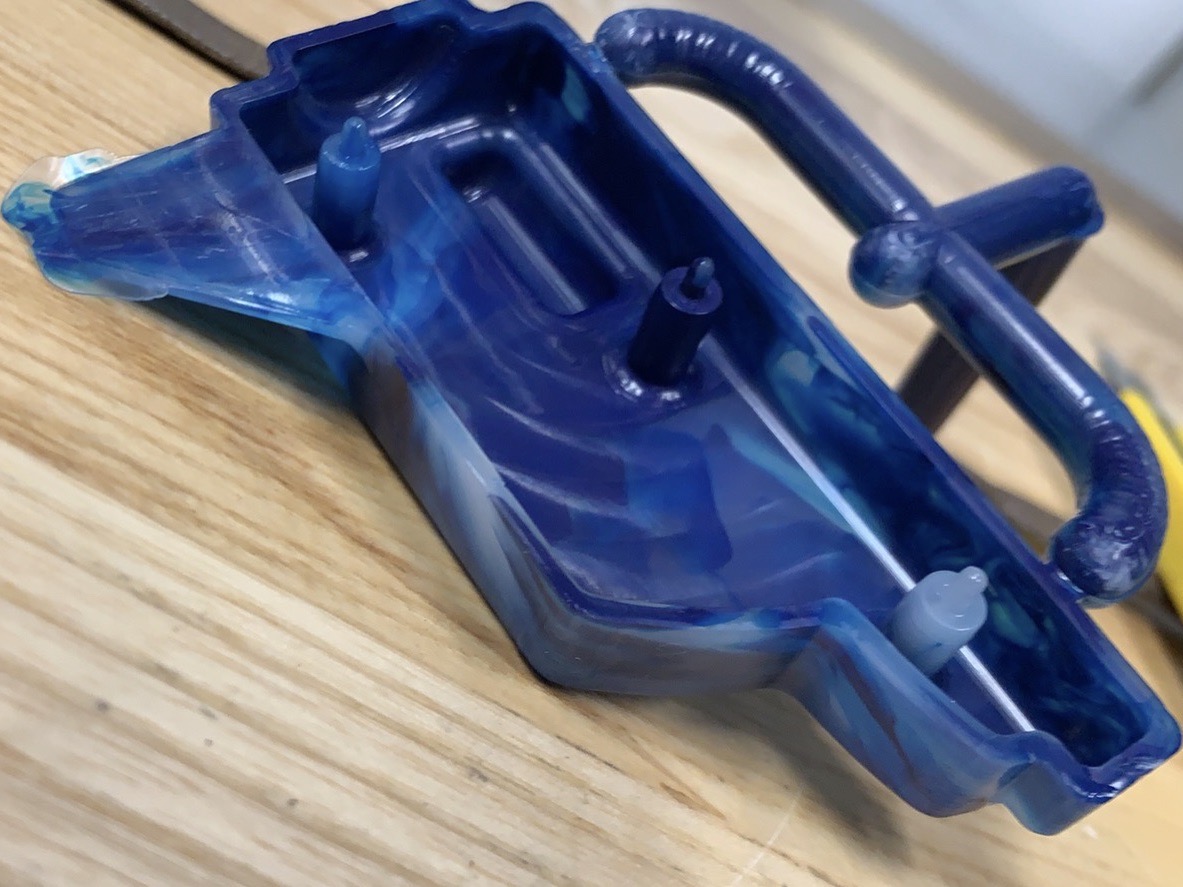

Final Toy

Reflection

Developed experience into the considerations that need to be taken in developing a successful injection molded part, from CNC machining to part assembly to operating the injection molder.